Current location:Home > Hebei Hankai piston wiper ring >

Hebei Hankai piston wiper ring

2025-08-14 17:49

2025-08-14 17:41

2025-08-14 17:40

2025-08-14 17:31

Selecting the right seal kit for your hydraulic ram is crucial. Factors to consider include the operating pressure, temperature, and the type of fluid used in the system Factors to consider include the operating pressure, temperature, and the type of fluid used in the system Factors to consider include the operating pressure, temperature, and the type of fluid used in the system Factors to consider include the operating pressure, temperature, and the type of fluid used in the system

Factors to consider include the operating pressure, temperature, and the type of fluid used in the system Factors to consider include the operating pressure, temperature, and the type of fluid used in the system seal kits for hydraulic rams. Materials like polyurethane, rubber, and PTFE (Teflon) are commonly used, each with its own advantages and suitability for specific applications.

seal kits for hydraulic rams. Materials like polyurethane, rubber, and PTFE (Teflon) are commonly used, each with its own advantages and suitability for specific applications.

Factors to consider include the operating pressure, temperature, and the type of fluid used in the system Factors to consider include the operating pressure, temperature, and the type of fluid used in the system

Factors to consider include the operating pressure, temperature, and the type of fluid used in the system Factors to consider include the operating pressure, temperature, and the type of fluid used in the system seal kits for hydraulic rams. Materials like polyurethane, rubber, and PTFE (Teflon) are commonly used, each with its own advantages and suitability for specific applications.

seal kits for hydraulic rams. Materials like polyurethane, rubber, and PTFE (Teflon) are commonly used, each with its own advantages and suitability for specific applications.

...

2025-08-14 17:29

2025-08-14 16:49

2025-08-14 16:20

2025-08-14 16:17

2025-08-14 16:10

2025-08-14 16:08

Latest articles

2. Design Specifications The unique design aspects, such as the sealing lip geometry and the hardness of the rubber, are optimized to balance flexibility and resilience. This design ensures proper contact with the shaft, reducing the risk of oil leakage and improving the overall efficiency of the machinery.

25 35 7 oil seal

Another important consideration when choosing a hydraulic oil seal is its installation method hydraulic oil seal sizes. Some seals are designed for press-fit installation, where they are inserted into the bore or onto the shaft using a tool or machine. Other seals may require adhesive or clamping methods to secure them in place. Proper installation is essential to ensure that the seal performs as intended and does not fail prematurely.

hydraulic oil seal sizes. Some seals are designed for press-fit installation, where they are inserted into the bore or onto the shaft using a tool or machine. Other seals may require adhesive or clamping methods to secure them in place. Proper installation is essential to ensure that the seal performs as intended and does not fail prematurely.

hydraulic oil seal sizes. Some seals are designed for press-fit installation, where they are inserted into the bore or onto the shaft using a tool or machine. Other seals may require adhesive or clamping methods to secure them in place. Proper installation is essential to ensure that the seal performs as intended and does not fail prematurely.

hydraulic oil seal sizes. Some seals are designed for press-fit installation, where they are inserted into the bore or onto the shaft using a tool or machine. Other seals may require adhesive or clamping methods to secure them in place. Proper installation is essential to ensure that the seal performs as intended and does not fail prematurely.The percentage of an oil seal refers to its ability to effectively prevent leakage. A higher percentage indicates a better sealing capacity, with 100% being the ideal value. However, in reality, achieving a perfect seal is often challenging. Therefore, oil seals with percentages ranging from 25% to 35% are commonly used in applications where a high level of sealing performance is required.

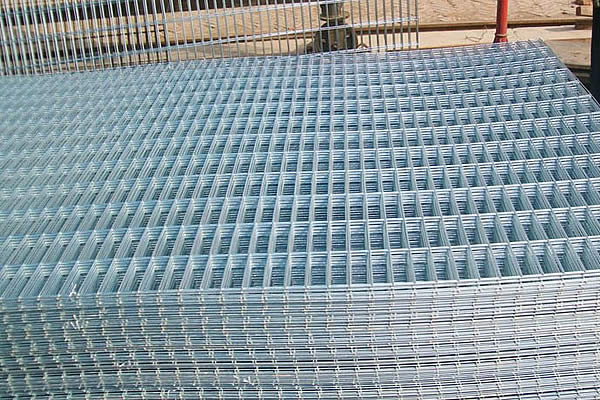

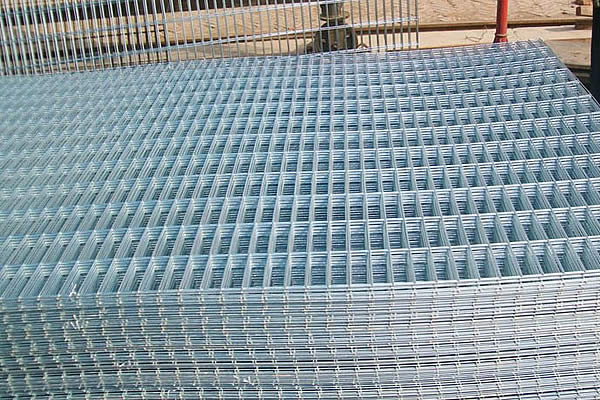

In industrial settings, galvanized steel wire mesh finds application in filtration systems, sieving materials, and even in manufacturing heavy-duty machinery guards galvanized steel wire mesh. It's also widely used in the mining industry for screening and sorting operations due to its resistance to abrasion.

galvanized steel wire mesh. It's also widely used in the mining industry for screening and sorting operations due to its resistance to abrasion.

galvanized steel wire mesh. It's also widely used in the mining industry for screening and sorting operations due to its resistance to abrasion.

galvanized steel wire mesh. It's also widely used in the mining industry for screening and sorting operations due to its resistance to abrasion.